Overhead Cranes That Work as Hard as You Do

When overhead cranes are critical to your operation, you can’t afford downtime, delays, or designs that don’t fit. At Zelus Material Handling, we don’t just build cranes, we deliver complete, start-to-finish solutions that keep your operation running smoothly.

Our Proven Process: Built Around Your Facility

We’ve refined a customer-first process to ensure every crane is a perfect fit for your facility, team, and goals:

Our Proven Process: See it in Action

We know cranes.

We'll make sure you know exactly what you'll need.

Book a free crane system consultation and get the right crane for your application

Why Zelus Material Handling?

Our customers don’t choose us because we’re the cheapest. They choose us because we make their life easier and their operation stronger.

The Complete Overhead Crane Partner

Full-service solutions for every stage, from design to maintenance and repairs.

We Solve It, No Matter What

We take ownership of your problem and work relentlessly until it’s fixed.

Expertise You Can Trust, People Who Care

A team with deep industry experience and a commitment to getting the job done right.

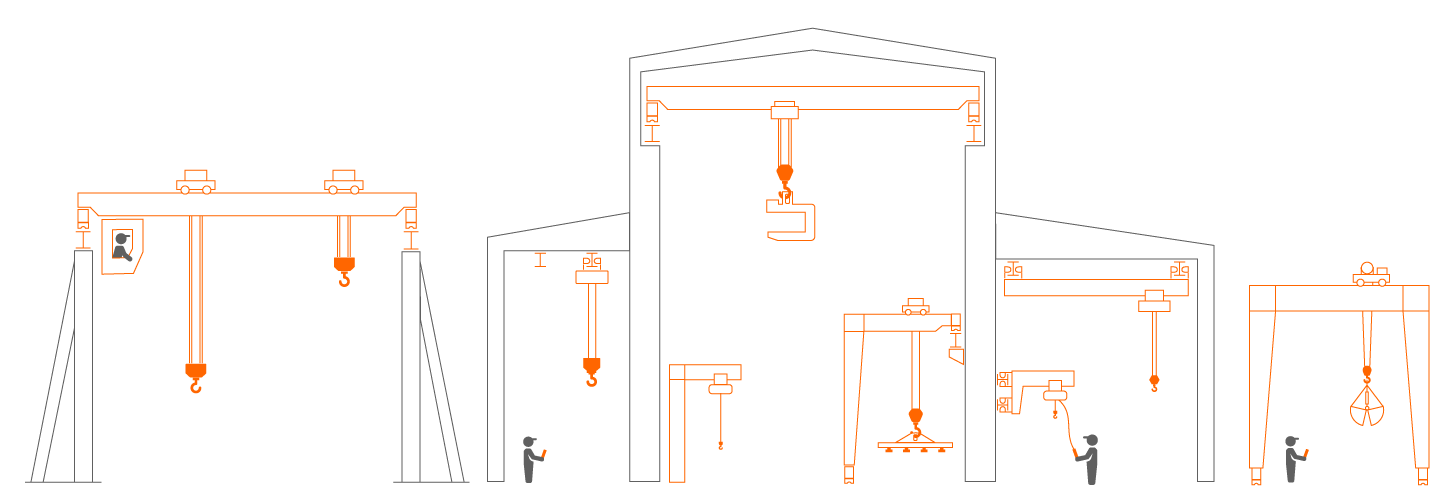

Free standing outdoor runway system with top running crane

Operator cab for ultimate visibility and control

Top running double girder crane with dual hoists for safe lifting of large loads

Top running hoist for double girder cranes

Runway beams and rails

Monorail systems for straight line movement or make a loop for continuous processes

Operator remote control for ultimate flexibility and control

Coil hook under hook attachment

Underhung wire rope hoist

Top running single girder crane

Jib crane for workstations

Electric chain hoist

Semi gantry crane for partial span lifting

Plate lifter or lifting beam under hook attachment

Under running crane for low headroom use

Underhung hoist

Wall mounted jib crane

Standard wired pendant control

Full gantry crane for use indoors or outdoors

Dry goods material bucket underhook attachment

Open winch top running hoist for double girder cranes

We are the manufacturer.

We have an ISO 9001:2015 registered manufacturing facility where we manufacture more than 100 cranes every year, ranging from standard to completely custom systems. We also manufacture crane components. Even though we have the largest crane manufacturing capacity in Ontario, we never make you feel like a number.

We design cranes that meet your needs, not ours. Whether you need to increase safety, maximize production capacity or reliability, or reduce costs, we deliver.

We Handle the Cranes So You Can Focus on Production

We know who we’re working for and we understand the pressure you’re under.

You need your cranes running. Always.

You don’t have time to babysit vendors.

You want clear communication, real reliability, and fewer headaches.

That’s exactly what Zelus delivers.